Somerset Stitch

Inspirational and sustainable stitch making in Somerset and beyond

Wednesday 10 April 2024

Boro Thread & Needle Holder

Wednesday 17 January 2024

Hand Needles

I use around 7 types of needles in the main and my make of choice is CLOVER - a long standing Japanese manufacturer, so named because the founder used clover leaves as book marks. There are numerous needle types and I particuarly like their Gold Eye feature for ease of threading. Most important is that when used correctly, Clover needles do not bend and they glide smoothly through fabric.

So to start with a general purpose needle. 'Sharps' took me through many years of every day use, however, however, they have recently been replaced by wonderous SELF-THREADING NEEDLES! No more searching for magnifiers or needle threaders, as they quickly thread by placing the thread in an indentation at the top of the needle and pulling the thread downwards - job done!

Next up are the EMBROIDERY NEEDLES, that I have long used for all kinds of embroidery. This mixed size pack is really useful as the needles will accommodate all kinds of thread. All sizes pierce fabric without too many layers easily and they have my favoured 'gold eye' - which brings me to the crucial topic of needle threading. I have a few tips to share on this, all of which avoids poking a frayed thread end at a needle eye!

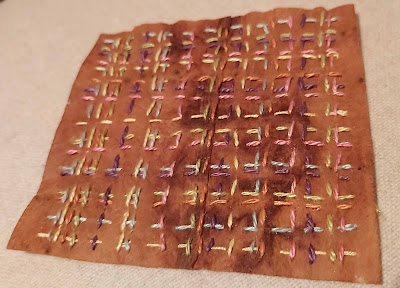

And one final tip for using a needle, particularly if like me you keep any length of nail. While mine are pretty short these days, a metal thimble is still beyond working for me and I have used a leather thimble with my hand stitching for many years. Having recently tackled projects with thicker layers and requiring a bit more welly, I've more recently found this Clover COIN THIMBLE with a metal piece on one side of the thimble to be useful for giving a needle a hard push.For anyone who has reached reading to this point, I commend you on your staying power through a pretty dry subject! I hope in recompense that I've been able to offer you some point of interest, if only that you will give a little consideration the next time you reach for a hand needle. An upside of writing this post is that I decided that a new needle case was long overdue - with hand stitching of course! My creation with Sashiko stitched bark fabric with silk thread, and silk and wool inners will add to my pleasure of hand needle selection I am sure - and I hope others too.

Sunday 26 November 2023

Quick Stitch - Origami Box

Origami made a lasting impression all the same and folding with fabulous fabric adds to the appeal. Reworking this box project from a few years back with recycled Kimono fabrics was most pleasurable - it's a very simple, yet striking project that can be created using any thin fabrics that give a sharp fold.

The starting point is cutting 12 equal circles of fabric, 6 each in two toning fabrics. Cut one of the pair of circles needs to be cut 0.25cm larger all around as this will become the box lid.Then to take one of each circle colour and stitch right sides together with as scant a seam as possible, leaving a gap of around 3cm in the seam for turning. Then turn the circles right sides out, neatly hand stitch the gap closed and carefully press the seams.

Then the origami bit comes into play by folding in the circled edges to create a squar. Do this for all size pieces, noting which of the 6 pieces is the slightly larger piece for the lid.Then the points of each square are folded back on themselves to make a smaller square, keeping tabs on that larger piece.

Take time with both of these folds to keep the pieces square and consistant - this will make the final construction very much easier.

A stiff insert is then made for the box sides - I used traditional pelmet vilene with an adhesive on one side - stiff card could also be used. Cut 5 inserts to tuck into the inside corners of the folded box sides and cut a slightly larger piece for the lid piece.Cut pieces of fabric larger than the inserts (1cm all the way around) and adhere these pieces to one side of the stiff insert. Fold over the edges and adhere to the back side of the card/vilene.

Wednesday 18 October 2023

Welsh Woollen Wanderings

Extending my textile wanderings in a westerly direction across the dramatic Prince of Wales Bridge has been very long overdue - as I've often been reminded when observing faintly on the horizon from one of my favourite Somerset coastline chill outs.

This said, my first wandering in Wales this year actually began on a Spring return journey from my Northern homeland - my first ever drive down the Welsh/English border to Builth Wells. This medieval market town has been the venue of Wonderwool Wales since its inauguration in in 2006 - to promote wool and fibre producers in Wales.The nuances of carding, drafting, spinning and plying are many and they are sure to generate lively debates! Thankfully spinners are a friendly breed in the main and they are happy to share and inspire those seeking to develop their skills.

Saturday 5 August 2023

Tea Bag Fabric

With sustainable fabrics becoming increasingly difficult to source, I thought that I would try my hand at making some tea bag fabric this summer and my kindly students have been helping out by drinking tea in abundance :)

So here's my starting point - a typical view in my kitchen area at the end of one of my workshop days. My tea bag of choice took a little researching as I sadly found that polypropylene plastic is still used in quite a few brands tea bags. With a strong desire to use an eco-friendly bag, I ultimately followed Jane Gray's lead and plumped for 'Clipper' Everyday Organic Tea for my initial experiments. The drying process is pretty simple - I leave the tea bags scrunched up as they are after use on a warm window sill with a bit of residual tea in the bottom of the dish.Once they have got to the point of being just damp, I open them out to finish drying off completely. Here are a near to dried bags in all their glory, with a beautiful patina and delicate patterns on the bag fabric.Sunday 18 June 2023

Orkney Sheep & Seaweed

Getting myself single-handedly to the Orkney island of North Ronaldsay had taken time, patience and a fair bit of holding my nerve - all of which paid off and gave me what had to be the most magical day of the year.

North Ronaldsay sheep are a primitive breed that live in the main around the 12 miles of coastline of this most northly Orkney isle of the same name. The popular story of their shoreline and seaweed eating lifestyle began in the early 1800s, with the creation of a 5ft high dyke being built around the island's shoreline - to keep the sheep from ravaging precious farmland. While a successful creation for landowners and sheep alike, maintaining such an immense structure intact on an island exposed to fierce elements is a mammoth task for a declined island population. An annual festival now helps to secure extra resources to enable repairs to the dyke, however, wall breeches throughout the year are inevitable. Combined with the fact that North Ronaldsay sheep can jump up considerable heights, it was soon evident that they happily eat grass and seaweed in equal measures - which can have serious consequences.